Automated Visual

& Optical Inspection

Inspectors Missing Subtle Defects

Higher Inspection Accuracy

Inability to Pinpoint Defects Precisely

Precise Localization of Defects

Inspection Bottlenecks Slow Production

Faster Inspection at Scale

Ensure Quality with AI-Powered Visual and Optical Inspection

Elevate your quality control processes with our AI2U-driven Automated Visual and Optical Inspection solution. Using advanced computer vision, our system analyzes product images and video streams in real time to detect defects, identify anomalies, and precisely locate issues—whether on industrial parts, packaging lines, or fresh produce.

From manufacturing lines to agriculture and logistics, our solution ensures consistency, reduces manual inspection errors, and enables faster decision-making. It not only flags problems but pinpoints the exact location within the visual data, allowing for targeted action and continuous improvement across your operations.

Services

Boosting Precision and Productivity with Visual Intelligence

Computer Vision (CV)

Powers real-time analysis of images and videos to detect surface defects, shape inconsistencies, or visual anomalies—whether in mechanical components or natural items like fruits and vegetables.

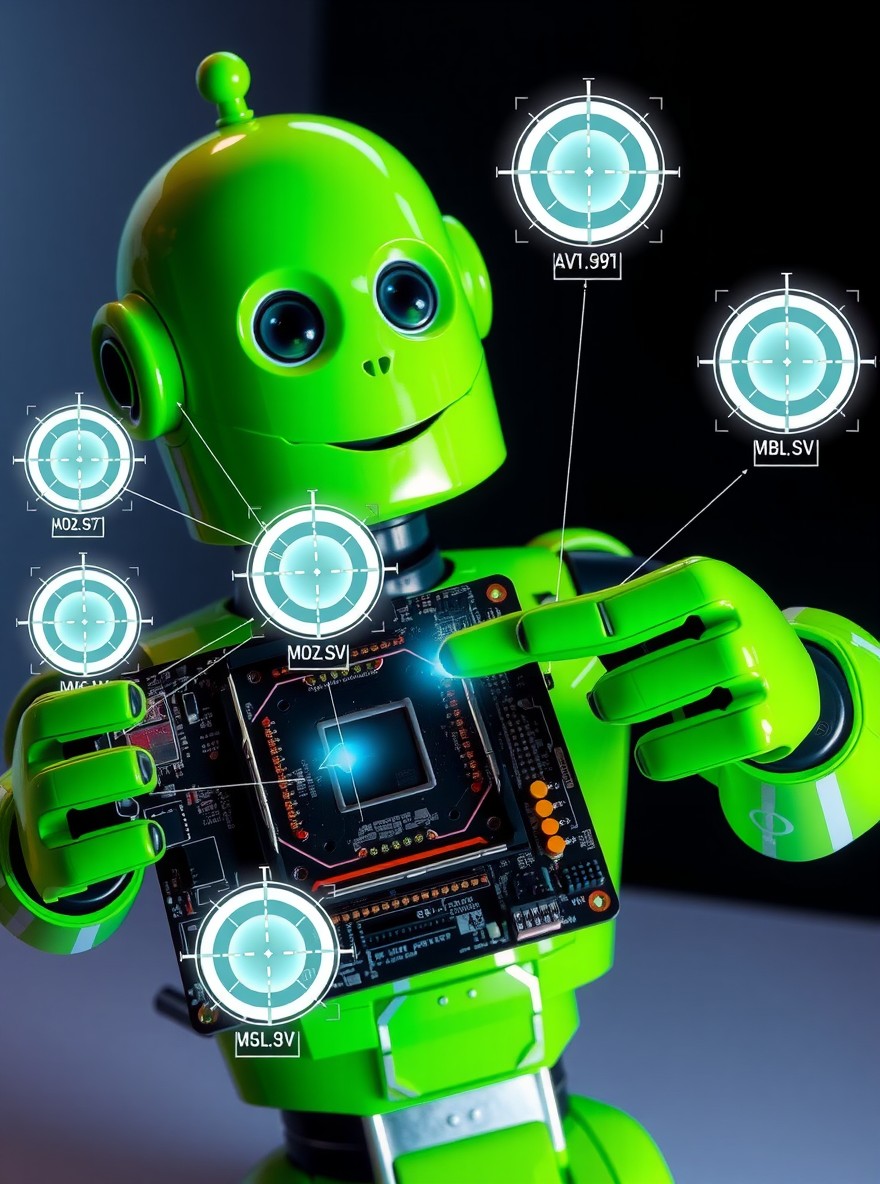

Image Segmentation & Object Detection

Breaks down visuals into precise regions to locate and classify defects, enabling pixel-accurate identification of anomalies in complex images.

State-of-the-art AI Models

AI2U Fine-tuned vision Model powers real-time analysis of images and videos to detect surface defects, shape inconsistencies, or visual anomalies—whether in mechanical components or natural items like fruits and vegetables.

Anomaly Detection & Pattern Recognition

AI2U pattern recognition learns from visual norms to flag irregularities that may not match historical quality standards—ideal for catching subtle or evolving defects.